The FRP Door is ideal for heavy traffic areas.

The FRP Door is ideal for heavy traffic areas.

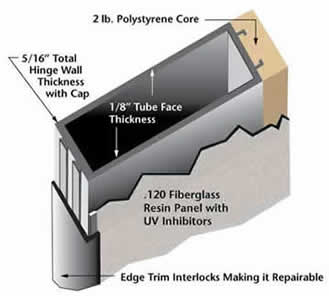

Inside the scratch and stain resistant FRP face sheet is an aluminum subframe and foam core which enable the door to withstand constant abuse and deflect damaging accidental impact and vandalism.

- Ideal for Institutional and Commercial Use

- Energy Efficient

- Strong and Lightweight

- Never requires Painting or Refinishing

- Continuous Hinges: Extra sturdy hinges evenly distribute the door’s weight over its entire length.

- Heavy Duty Structural Components

- Custom Door Sizes Readily Available

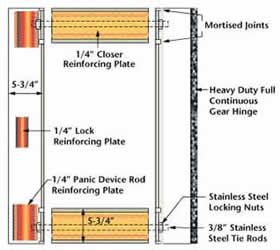

REBCO carries various FRP doors to meet any standard your entrance needs may require. All models can be altered with custom reinforcements to insure hardware retention in the most demanding of venues.

All FRP doors are constructed with interlocking aluminum edge trim designed for easy component breakdown and field repair. In concealed hardware applications where others are forced to cut, splice or weld their side rails to accommodate concealed vertical rod hardware, thereby weakening the door leaf, our doors remain strong.

REBCO offers a 3.5" rail, medium stile door which can perform under the most difficult of circumstances. With a 1/8″ tube face thickness and a 3/16″ hinge wall thickness this model can withstand the toughest traffic and abuse. It is particularly useful in concealed hardware applications.

REBCO offers a 3.5" rail, medium stile door which can perform under the most difficult of circumstances. With a 1/8″ tube face thickness and a 3/16″ hinge wall thickness this model can withstand the toughest traffic and abuse. It is particularly useful in concealed hardware applications.

Our heaviest most durable FRP door has side rails that are 5 3/4″ across the tube face. This model will withstand all the abuse found at industrial buildings and secondary schools and still perform flawlessly. Constructed of 6063-T6 alloy this product can be produced at widths up to 48″ and heights to 120″.